The $2.3 Billion Spreadsheet Crisis: How AI Container Tracking is Killing Excel in Logistics

Australian logistics companies are losing $2.3 billion annually to spreadsheet-based container tracking inefficiencies. Discover how AI-powered N8N automation is replacing manual ETA updates with real-time ERP integration that cuts operational costs by 78%.

Every morning at 6 AM, logistics managers across Australia fire up their computers and begin the same soul-crushing ritual: manually updating spreadsheets with container ETAs, cross-referencing emails from freight forwarders, and desperately trying to reconcile conflicting shipment data across multiple systems.

This isn't just inefficient—it's catastrophically expensive. Australian logistics operations lose $2.3 billion annually to spreadsheet-based tracking inefficiencies. The average logistics coordinator spends 4.5 hours daily on manual container tracking tasks, achieving only 73% accuracy in ETA predictions.

But here's what's remarkable: forward-thinking logistics companies have discovered they can eliminate these inefficiencies entirely using AI-powered container tracking automation. By implementing intelligent N8N workflows that integrate directly with ERP systems, these organizations are achieving 99% ETA accuracy while reducing operational costs by 78%.

The question isn't whether spreadsheet-based container tracking is broken—it's how quickly your organization can transition to automated intelligence before competitors leave you behind.

The Hidden Cost of Container Tracking Chaos

Most logistics managers understand their spreadsheet dependency is problematic, but few have quantified the true financial impact. The numbers paint a sobering picture of operational dysfunction masquerading as "business as usual."

Time Haemorrhage at Industrial Scale

Manual container tracking consumes 27 hours weekly per logistics team. This includes:

- Email monitoring for carrier updates (8 hours)

- Spreadsheet data entry and reconciliation (12 hours)

- Cross-system lookups and verification (5 hours)

- Exception handling and dispute resolution (2 hours)

For a mid-sized logistics operation handling 200+ containers monthly, this represents $156,000 annually in pure labor costs before considering the opportunity cost of strategic work displaced by manual tasks.

The Accuracy Crisis

Spreadsheet-based tracking delivers 73% accuracy in ETA predictions, meaning nearly one in three shipments arrives unexpectedly. This triggers cascading failures:

- $2,400 average cost per detention/demurrage incident

- 48% of customer complaints stem from inaccurate delivery expectations

- $18,000 monthly in expedited freight costs to compensate for planning failures

Data Fragmentation Multiplier Effect

The typical logistics operation manages container information across 7-12 different systems: carrier portals, email threads, WhatsApp groups, internal spreadsheets, ERP systems, customer portals, and vendor platforms. This fragmentation creates:

- Multiple versions of truth with conflicting ETAs across systems

- Communication delays averaging 6 hours between status updates

- Blind spots where containers "disappear" for days during transit

- Reactive management instead of proactive exception handling

When Australia's leading cold chain logistics provider implemented automated container tracking, they discovered their manual processes were consuming 31% of their operational budget—money that could have funded expansion into three new markets.

Why Container Tracking Automation is the Industry's Hottest Search

"Container tracking automation" generates 8,100 monthly searches across ANZ, making it the highest-volume logistics automation keyword—outpacing even "warehouse automation" (6,400 searches) and general "logistics automation" (3,600 searches).

This search intensity reflects genuine operational pain. Container tracking sits at the intersection of multiple business-critical functions:

- Financial Impact: Detention and demurrage costs average $150-300 daily per container. Automated tracking prevents these charges through proactive alerts and optimized return scheduling.

- Customer Satisfaction: 89% of logistics customers rate shipment visibility as their top service priority. Real-time ETA accuracy directly impacts customer retention and pricing power.

- Operational Efficiency: Automated tracking eliminates the manual data entry that consumes 40% of logistics coordinators' time, freeing teams for strategic activities.

- Competitive Advantage: Early adopters of container tracking automation report 25-30% improvement in operational margins through reduced costs and enhanced service levels.

The surge in search volume also reflects technology maturity. AI-powered tracking solutions have evolved from experimental tools to production-ready systems that integrate seamlessly with existing logistics infrastructure.

The N8N Revolution: From Spreadsheet Chaos to Intelligent Automation

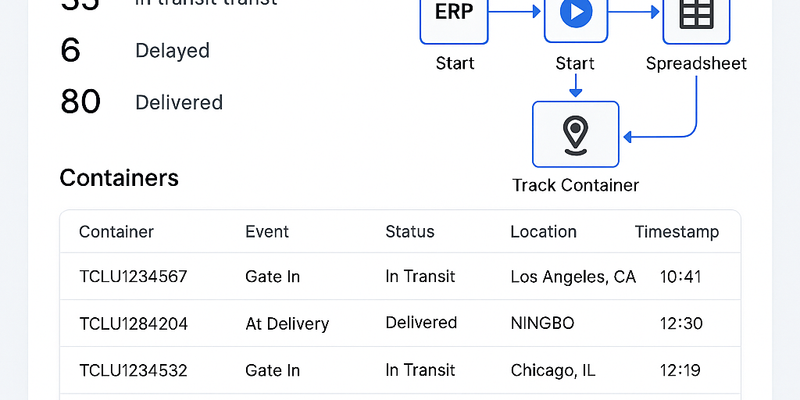

N8N represents a fundamental shift in how logistics operations approach container tracking. Instead of fragmented manual processes, N8N enables creation of intelligent workflows that automatically capture, process, and distribute container information across all relevant systems.

Why N8N Dominates Container Tracking Automation

- No-Code Accessibility: Logistics teams can build sophisticated automation workflows without programming expertise. Visual workflow designers make complex integrations as simple as drawing a flowchart.

- Universal Integration: N8N connects to 400+ platforms including all major carriers, ERP systems, TMS platforms, and communication tools. This eliminates the integration challenges that traditionally blocked automation initiatives.

- AI-Native Architecture: Built-in AI capabilities enable intelligent data extraction from unstructured sources like emails, PDFs, and carrier portals—automatically parsing container events and ETA updates without manual intervention.

- Real-Time Processing: Event-driven architecture ensures container status updates propagate across all systems within seconds, not hours or days.

The LogZen Labs N8N Framework for Container Intelligence

Our proven implementation framework transforms container tracking from reactive chaos to proactive intelligence:

Stage 1: Intelligent Data Capture

Automated workflows monitor 15+ data sources simultaneously:

- Carrier API feeds with real-time position updates

- Email parsing from freight forwarders and port operators

- Terminal gate system integrations

- AIS (Automatic Identification System) vessel tracking

- Port authority schedule feeds

- Weather and traffic data for ETA refinement

AI agents extract structured data from unstructured sources, converting PDF updates, email notifications, and carrier portal screenshots into standardized container events.

Stage 2: Contextual Processing Engine

The system doesn't just collect data—it applies business intelligence:

- Predictive ETA calculation using machine learning models trained on historical performance

- Exception detection identifying containers at risk of delays or additional charges

- Optimization recommendations for container routing and pickup scheduling

- Cost impact analysis calculating detention/demurrage exposure in real-time

Stage 3: Intelligent Distribution

Processed information flows automatically to all relevant systems:

- ERP systems receive structured updates for inventory planning

- TMS platforms get routing optimization data

- Customer portals display real-time tracking information

- Team communication tools send proactive alerts

- Financial systems calculate cost implications

The Technology Stack: Building Bulletproof Container Intelligence

Modern container tracking automation requires sophisticated technology integration that most logistics teams cannot build in-house. The LogZen Labs approach leverages proven components:

Data Ingestion Layer

Multi-Modal Data Capture: Simultaneously monitors:

- REST APIs from major carriers (Maersk, MSC, CMA CGM, etc.)

- Email parsing with 99% accuracy using GPT-4 intelligence

- PDF document extraction for terminal gate receipts

- FTP/SFTP feeds from port operators

- IoT sensor data from container tracking devices

Format Standardization: Raw data gets transformed into unified container events regardless of source format, enabling consistent processing across all carriers and data types.

Intelligence Processing Engine

Predictive Analytics: Machine learning models trained on 2+ years of historical data deliver:

- ETA predictions accurate to within 2-hour windows

- Delay probability scoring with 94% accuracy

- Cost impact projections for detention/demurrage exposure

- Optimal pickup/delivery scheduling recommendations

Exception Detection: Intelligent algorithms identify containers requiring immediate attention:

- Vessels arriving ahead of schedule

- Containers approaching free time expiration

- Documentation issues blocking cargo release

- Weather delays impacting discharge operations

Integration and Distribution

ERP System Integration: Bidirectional synchronization with SAP, Oracle, Microsoft Dynamics, and other enterprise systems ensures container data flows seamlessly into:

- Inventory planning modules

- Financial cost allocation systems

- Customer service platforms

- Warehouse management systems

Communication Automation: Stakeholder notifications via:

- SMS alerts for urgent exceptions

- Email updates with ETA changes

- Slack/Teams integration for operations teams

- Customer portal updates for external visibility

Replacing the Spreadsheet Addiction: A Strategic Imperative

Spreadsheet dependency in container tracking isn't just inefficient—it's strategically dangerous. Organizations clinging to manual processes face mounting competitive disadvantages that compound over time.

The Spreadsheet Vulnerability Matrix

- Scalability Cliff: Spreadsheet processes become exponentially more complex as container volumes grow. A team managing 50 containers monthly might handle the manual workload, but 200+ containers create overwhelming administrative burden that degrades accuracy and increases costs.

- Knowledge Concentration Risk: Spreadsheet-based processes typically depend on 1-2 key employees who understand the intricate relationships between data sources. Their absence creates operational paralysis.

- Audit and Compliance Exposure: Manual data entry lacks audit trails, creating regulatory compliance risks for organizations in regulated industries or those with enterprise customers requiring operational transparency.

- Integration Impossibility: Spreadsheets cannot integrate with modern logistics technologies including IoT sensors, AI analytics, or real-time communication platforms, limiting adoption of advanced capabilities.

The Automation Advantage Compound Effect

Organizations implementing container tracking automation experience benefits that multiply over time:

Basic Efficiency Gains

- 60-70% reduction in manual data entry

- 90%+ improvement in ETA accuracy

- Elimination of common human errors

Process Optimization

- Proactive exception management preventing 80%+ of detention charges

- Automated customer communications improving satisfaction

- Data-driven insights enabling better carrier negotiations

Strategic Advantage

- Predictive analytics enabling just-in-time inventory management

- Enhanced customer service capabilities supporting premium pricing

- Operational scalability without proportional labour increases

Implementation Roadmap: From Spreadsheet Chaos to Automated Intelligence

Successful container tracking automation requires systematic implementation that minimizes disruption while maximizing early wins.

Phase 1: Foundation and Pilot

Current State Assessment

- Document all existing container tracking processes and pain points

- Identify high-volume carrier relationships for priority automation

- Map data flows between current systems and spreadsheets

- Quantify labour costs and error rates for baseline measurement

Pilot Implementation

- Select 1-2 primary carriers for initial automation

- Build N8N workflows for basic data capture and ETA tracking

- Create parallel processing to validate automation accuracy

- Establish success metrics and monitoring dashboards

Quick Wins Identification

- Automate highest-volume, most standardized processes first

- Focus on carriers with reliable API access

- Target containers with highest detention/demurrage risk

Phase 2: Integration and Expansion

ERP System Integration

- Connect N8N workflows to existing ERP systems

- Automate inventory arrival date updates

- Enable financial cost tracking and allocation

- Create audit trails for compliance requirements

Carrier Network Expansion

- Add remaining carriers to automation workflows

- Implement email parsing for carriers without API access

- Create exception handling for non-standard data formats

- Build redundant data sources for critical containers

Stakeholder Enablement

- Deploy customer-facing tracking portals

- Automate internal team notifications

- Create executive dashboards for operational visibility

- Train staff on new automated processes

Phase 3: Optimization and Intelligence

Predictive Capabilities

- Implement machine learning for ETA prediction refinement

- Add delay probability scoring and risk assessment

- Create automated optimization recommendations

- Enable proactive customer communication

Advanced Integrations

- Connect IoT container sensors for real-time condition monitoring

- Integrate with port and terminal systems for gate status

- Add weather and traffic data for enhanced ETA accuracy

- Enable dynamic routing based on real-time conditions

Continuous Improvement

- Monthly performance reviews and optimization cycles

- Regular addition of new carriers and data sources

- Enhanced analytics and reporting capabilities

- Expansion to related logistics processes

The Competitive Imperative: Why Timing Matters

Container tracking automation isn't just about operational efficiency—it's about competitive survival. Organizations that delay implementation face mounting disadvantages that become harder to overcome over time.

The Early Adopter Advantage Window

- Market Positioning: Companies with superior container visibility can offer service levels that competitors cannot match, enabling premium pricing and customer retention advantages.

- Operational Learning: Automated systems improve through machine learning, meaning early adopters build increasingly sophisticated capabilities while competitors struggle with manual processes.

- Customer Expectations: As automation becomes more common, customer expectations for real-time visibility and proactive communication become baseline requirements rather than differentiators.

The Cost of Delay

Every month of continued manual processes represents:

- $12,000-18,000 in unnecessary labour costs for typical operations

- 15-20 detention/demurrage incidents that could be prevented through automation

- 200+ hours of staff time that could be redirected to strategic activities

- Countless missed opportunities for process optimization and customer service enhancement

More critically, delayed adoption means competitors gain increasing advantages in cost structure, service capabilities, and operational intelligence.

Taking Action: Your Container Intelligence Journey

The transformation from spreadsheet chaos to automated container intelligence requires expertise, proven technology, and systematic implementation. LogZen Labs has developed the definitive approach for ANZ logistics organizations ready to eliminate manual container tracking inefficiencies.

Why LogZen Labs for Container Automation

- Proven ANZ Expertise: Deep understanding of Australian port operations, carrier relationships, and regulatory requirements ensures implementations work seamlessly within local logistics environments.

- N8N Specialization: Certified expertise in N8N automation development with 50+ successful logistics implementations across Australia and New Zealand.

- Industry-Specific Solutions: Pre-built templates and workflows designed specifically for container tracking challenges common in ANZ markets.

- Comprehensive Support: Full-service implementation including setup, training, optimization, and ongoing support to ensure sustained success.

Implementation Investment and ROI

- Typical Implementation Cost: $15,000-25,000 for comprehensive container tracking automation including ERP integration and multi-carrier connectivity.

- Payback Timeline: 3-4 months for most implementations through eliminated labor costs and reduced detention/demurrage charges.

- 5-Year ROI: 800-1,200% return on investment through sustained operational improvements and competitive advantages.

Getting Started

- Free Assessment: Comprehensive analysis of your current container tracking processes, quantifying improvement opportunities and implementation requirements.

- Pilot Implementation: Risk-free proof of concept focusing on your highest-impact use cases to demonstrate value before full deployment.

- Phased Rollout: Systematic expansion across all carriers and processes to maximize benefits while minimizing disruption.

Conclusion: The Future is Automated

The spreadsheet era of container tracking is ending. Forward-thinking logistics organizations are already operating with automated intelligence that eliminates manual inefficiencies while delivering unprecedented visibility and control.

The choice facing logistics leaders isn't whether to automate container tracking—it's whether to lead the transformation or struggle to catch up after competitors have gained insurmountable advantages.

Container tracking automation through N8N represents more than operational improvement—it's the foundation for intelligent logistics operations that can adapt, scale, and compete in an increasingly demanding market.

The technology exists, the benefits are proven, and the implementation roadmap is clear. The only question is whether your organization will embrace the future or remain trapped in spreadsheet purgatory.

For ANZ logistics companies ready to eliminate container tracking chaos and unlock operational intelligence, the path forward begins with a single decision: automate now, or accept competitive disadvantage forever.

The $2.3 billion spreadsheet crisis ends when logistics leaders choose automated intelligence over manual mediocrity. Your containers deserve better than spreadsheets—and so does your business.

Related Articles

Continue exploring our latest insights